Complementary pipeline tools

MEIDE has a wide range of tools for cutting grooves, rolling grooves, making holes, and cutting pipes on pipelines. These tools are widely applicable and provide customers with a one-stop comprehensive service.

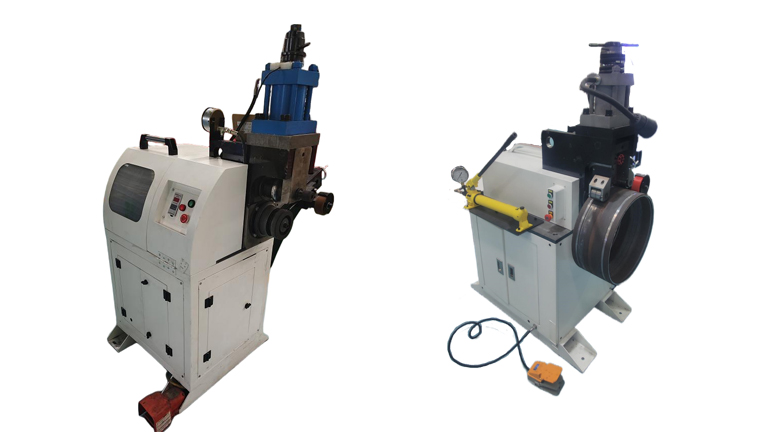

Complementary pipeline tools-Roll Grooving Machine

Pipe Processing Size:DN25-DN1800

Groove Depth:≤20mm

Product advantages and features: Automation, superior performance, greater convenience. Automatic groove rolling. When the groove processing reaches the predetermined depth, the equipment will automatically stop running; all parameters have high precision, and the processed pipe material has no deformation or flared mouth phenomenon; the equipment structure is optimized, the main unit and the support frame are innovatively separated into two independent parts, with a portable design, convenient for various working conditions.

Pipe Tools—Cut Grooving machine Patented structure, an industry-first innovation (Patent No.: CN119870989A)

Pipe Processing Size:DN50-DN900

Groove Depth:2-8mm

Product advantages and features: High efficiency, excellent performance, high precision, intelligent digitalization.

Its efficiency is more than three times that of similar equipment; the processing performance is outstanding, with one-time slot cutting and forming, extremely efficient, and eliminating the need for rework; it is not afraid of elliptical pipes, with a processing depth deviation of 0.2mm; it has unique functions such as excessive tool wear reminder, processing efficiency recording and data sharing, which are unique in the industry.